Pigmento laranxa 43-Corimax Laranxa GR

Parámetros técnicos de pigmento laranxa 43

| Índice de cores Nº. | Laranxa pigmento 43 |

| Nome do produto | Corimax Orange GR |

| Categoría do produto | Pigmento orgánico |

| Velocidade da luz (revestimento) | 7 |

| Resistencia ao calor (revestimento) | 200 |

| Velocidade da luz (plástico) | 7-8 |

| Resistencia ao calor (plástico) | 280 |

Cor |  |

| Distribución de tonalidades |

Aplicación :

Recomendado para pinturas automotivas, pinturas industriais, revestimentos en po, pegadas de impresión, PVC, caucho, PS, PP, PE, PU, tintas a base de auga, tintas solventes, tintas UV.

Suxerido para revestimentos arquitectónicos, revestimentos de bobinas, tintas compensadas.

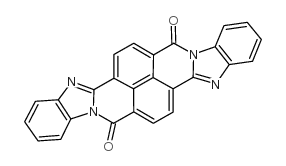

Estrutura molecular:

Propiedades físicas e químicas:

Solubilidade: insoluble en acetona, alcol, cloroformo e tolueno, lixeiramente soluble en o-clorofenol e piridina; amarela claro vermello escuro en ácido sulfúrico concentrado; cor oliva (fluorescencia vermella) en po alcalino seguro, claro vermello en caso de marrón ácido.

Hue ou light: laranxa, vermello laranxa claro.

Densidade relativa: 1,49-1,87

Densidade a granel / (lb / gal): 12.4-15.6

Punto de fusión / ℃: 460

Tamaño medio de partícula / μm: 0,07

Forma de partícula: corpo en forma de vara

Superficie específica / (m2 / g): 46 (GR)

Valor do pH / (10% suspensión): 7

Absorción de aceite / (g / 100g): 96

Potencia de cobertura: tipo transparente

Uso do produto

A estrutura molecular do pigmento é isómero trans, dando unha cor vermella laranxa. Hostaperm Orange GR ten unha superficie específica de 46 m2 / g. Velocidade de luz e intemperie de grao 7-8. Usado para a coloración do puré de acrilonitrilo (PAN) (pano, lona e tenda), colorante de poliestireno transparente, soluble en poliéster termoplástico para dar unha cor amarela; brillo metálico en pintura con pasta metálica de aluminio; resistencia ácido / álcali Excelente, tamén indicado para recubrimentos de látex ao aire libre.

Principio de síntese:

Reacción de condensación do ácido 1,4,5,8-naftalenetetracarboxílico con o-fenilendiamina a 120 ºC no medio de ácido acético glacial para xerar cis (azul-vermello) e trans (amarelo-vermello) A mestura separou mediante diferente solubilidade. en disolución de etanol hidróxido de potasio, quentada a 70 ° C durante 1 H, precipitouse o isómero trans, filtrouse e hidrolizouse o pigmento cru para preparar o pigmento CI laranxa 43 mediante un tratamento de pigmentación.